TSS43H Natural Gas Trap Valve

manufacturer: Shanghai MeiYan Yi Pump & Valve Co., Ltd.

Eml: sales@1bengfa.com

Tel: +86 (21) 5640 2009

Mob: +86 138 1691 3072(WeChat Same Account)

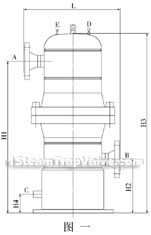

product drawing

TSS43H natural gas trap valves

TSS43H Series natural gas trap valve ia an automatic zero-leakage newly trap valve, under no other motive power condition, the production make use of ball-float and lever-balance principle to achieve the purpose of gas-water separation for natural gas and automatically draining depositing water(liquid) in the natural gas storage tank without gas-leakage. it can apply to any working condition with best energy-saving and environment-protection effect.

Functional features

1. Automatically continously working, no-water-shuting off, the emission rate of depositing water(liquid) is 100%

2. Gas-resistance is rigour without any leakage.

3. Sewage subside automatically, sewage disposal at regular intervals, with strong sewage-resistance capability,and no blocking phenomenon.

4. The material of internal components are all stainless steel,the inner wall has been delt with corrosion-resistance, so the useful life is longer.

5. Convenient installation, no debugging, balanced operating, no noise, safe and reliable.

Dimensions & constructral diagram

TSS43H natural gas trap valve constructral diagram

Technical features

| Type | Nominal diameter(mm) | Nominal pressure(MPa) | Working pressure(MPa) | Working temperature(℃) | Displacement(m3/h) | Leakage rate(Gas)(%) | Discharge rate(liquid)(%) |

| TSS43H-16 | 25 32 40 50 65 80 100 150 | 1.6 | ≤1.0 | normal temperature | 2-50 | 0 | 100 |

| TSS43H-25 | 2.5 | ≤1.6 | |||||

| TSS43H-40 | 4.0 | ≤2.0 | |||||

| TSS43H-63 | 6.3 | ≤3.5 | |||||

| TSS43H-100 | 10.0 | ≤6.3 |

TSS43H external diagram

A、water inlet B、 outlet C、 drain outlet D、gas-return hole E、 pressure gage (picture one)

Type specification parameter installation dimensions

TSS43H Natural gas trap valve can drain the mixed liquid of oil, water and condensateoil.(eg, Table one)

If the natural gas contains H2S gas, you should choose sulphur-resistance type natural gas trap valve, ” K “is added in front of the sulphur-resistance type natural gas trap valve. The type in the bracket is the corresponsing type of sulphur-resistance trap valve.

Table One

| type | nominal pressure(MPa) | max. working pressure MPa | outlet and inlet flange | displacement(t/h) | installation dimensions(mm) | ||||

| DN | PN | H1 | H2 | H3 | L | ||||

| TSS43H-63 (KTSS43H-63) | 6.3 | 3.5 | 50 | 6.3 | 8、10 | 950 | 360 | 1350 | 555 |

| Remarks | 1. connecting dimensions of drain outlet:ball valve with pipe connector DN20 PN6.3 H4=100 2. connecting dimensions of gas-return hole:DN10 PN6.3 3. flange standard:DN50 PN6.3 JB/T82.2-94A type 4. all the specifications have the same installation dimensions | ||||||||

Selecting ways of natural gas trap valve

1. The max. working pressure of draining point can not exceed upper limit of working pressures listed in Table One.

2 . The displacement listed in Table One indicates the quantity of continous emission for one hour when the corresponding working pressure is arrived. Users should accord to 2-5 times of liquid-producion quantity of the actual average hours to choose the proper diaplacement specification in the Table, according to actual working pressure of work condition and the inhomogeneity of producing fluid. The bigger of the space between the actual working pressure and the upper limit, the more uneven of the liquid-production quantity. The bigger of the liquid-production quantity referred to the femur-shaped liquid in short time, the higher diaplacement times you should choose.

Installation

In the new opened well project, the installation of natural gas trap valve should be after that the main project is finished and the systematic pressure-test and piperoad blowing working are completed. If the installation of trap valve is before pressure-test and pipeline blowing, the natural gas trap valve should be separated from system, and enable the bypass pipeline to blow to avoid pullution to the internal of the trap.

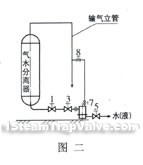

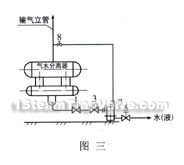

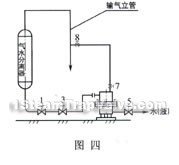

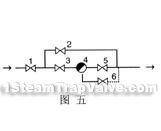

natural gas trap valve installation schematic diagram

1. scupper valve of natural gas water-gas separator

2. bypass valve

3. inlet fore-end valve of natural gas trap valve

4. natural gas trap valve

5. hydrophobic port valve

6. drain outlet valve

7. gas-return port valve

8. reture pipe valve