Combined Type Superheated Steam Trap Valve

manufacturer: Shanghai MeiYan Yi Pump & Valve Co., Ltd.

Eml: sales@1bengfa.com

Tel: +86 (21) 5640 2009

Mob: +86 138 1691 3072(WeChat Same Account)

product drawing

Combined type superheated steam trap valves

production introduction

Compound superheated steam trap, structure is reasonable and advanced. In overheating, high pressure, and low-loading work condition, can timely emissions of condensed water generating after the superheated steam disappears, effectively prevent overheating steam leakage, high quality of work. The highest temperature is 550 degrees, the body as a whole stainless steel, hard alloy steel seat for high-temperature-abrasion-resistance,and long service life, is special trap for superheated steam. This valve is the special reap for high-temperature, high-pressure, superheated steam piping and heating equipment.

Dimensions & constructral diagram

Combined type superheated steam trap valve constructral diagram

Main performance and parts

| Material of parts | Body | 1Cr18Ni9Ti | Performance parameter | SH64P | Nominal pressure 6.4 MPa |

| Main seat, Disc | stellite | SH100P | Nominal pressure 10.0MPa | ||

| Sub-valve cup-float | 1Cr18Ni9Ti | Working medium | Superheated steam, condensed water | ||

| Lever, bucket | 1Cr18Ni9Ti | Max.working temperature | 550℃ | ||

| Gas-inlet pipe, water-inlet pipe | 1Cr18Ni9Ti | Max. permitting temperature | 550℃ |

Working principle

It is the internal structure of the inverted barrel and ball-float as start elements,is divided into two isolation valve chamber, which is connected by two stainless steel tube. Starting device, air and condensed water appeared at the pipe,now the trap is overall open, so the air exhausts quickly, when the condensed water enter quickly into the lower cavity, ball-float level rise by the rising liquid level, pipe inlet hole sealed. The condensed water up to the main valve catheter cavitym, inverted barrels sinking cause the connecting rod to open the main valve, discharge condensed water, device quickly improve temperature. When the water level of the vice valve chamber reduces, ball-float down with the level drops, vice valve is opened, the steam goes into inverted bucket of the the main valve lumen from the inlet steam pipe, the barrel of buoyancy generated upward, shut off the main valve with the connecting rod. When the water level of vice valve again rises, the next cycle starts, uninterrupted drainage.

Type, specification and external dimension table

| Type | Diameter | Connecting model | Overall height Hmm | DIAMETER Bmm |

| SHY64P-E | 15 20 25 | Thread | 303 | 108 |

| SHY64P-F | Flange | 334 | 108 | |

| SHY64P-W | Socket Weld | 303 | 108 | |

| SHY100P-F | Flange | 468 | 112 | |

| SHY100P-W | Socket Weld | 303 | 112 | |

| (SH represent high-pressure superheated steam series) Flange-connection abide by native standard or HG20596, 20618-97 or user’s requirement to manufacture. | ||||

Displacement table

| Type | Seat NO. | △P pressure difference/(Displacement kg/h) | ||

| 4.0Mpa | 5.0Mpa | 8.0Mpa | ||

| SHY64P-W.E.F | GN40 | 368 | ||

| GN64 | 252 | 285 | ||

| SHY100P-W.F | GN100 | 166 | 189 | 230 |

Correct model-selection conditions for order

Users choose the displacement of the trap according to the the largest quantity of condensed water, that is the largest steam consumption of steam-used equipment multiply selecting multiplying power(from double to triple ).

The highest pressure difference of trap is valve front pressure to subtract back pressure, the back pressure should be marked out if possible.

The highest working temperature of trap valve

Using work condition of trap.

Connecting model

Material of body

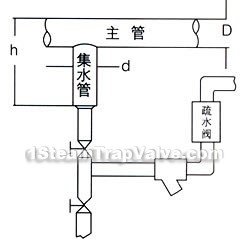

Discharge schematic diagram of main pipeline condensed water

Effect from collecting pipe dimension

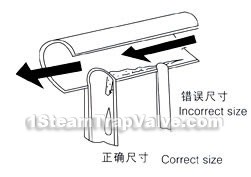

installation items:

Under the superheated high-pressure small loading conditions, the collecting pipe and the internal trap only produce very small quantity of condensed water, selecting supersmall collecting pipe will cause drawing-in phenomenon.

Steam mian pipeline dimension(D) is within 150mm, recommended collecting pipe dimension (d) is the same as that of main pipeline; if main steam pipeline dimension(D) is from 300mm to 350mm, the recommended collecting pipe dimension (d) is 150mm.

The smallest length dimension of collecting pipe (h) is 700mm.