Bell-shaped Float-type Steam Trap Valve

manufacturer: Shanghai MeiYan Yi Pump & Valve Co., Ltd.

Eml: sales@1bengfa.com

Tel: +86 (21) 5640 2009

Mob: +86 138 1691 3072(WeChat Same Account)

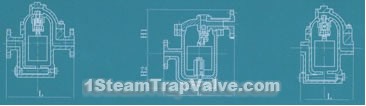

product drawing

ER105F/ER110/ER116/ER120 Bell-shaped float-type steam trap valves(pic1)

ER105 Bell-shaped float-type steam trap valve(pic2)

ER25 Bell-shaped float-type steam trap valve(pic3)

Features and performance

2.1 High adaptability to emergence size of condensation water, not only intermittent discharge, but also continuously.

2.2 The internal is equipped with large displacement of double valve seat differential pressure machinery and SCCV closing system, volume is small but displacement is large.

2.3 The internal parts adopt stainless steel to manufacture and are all installed in the bonnet, so the maintenance is extremely convenient.

2.4.The rate of back pressure is 90% higher.

2.5.The gas and water are separated reliably(water vapor go in from bottom of the valve by u-shaped channel), the internalis always in the state of water seal, effectively prevent the leakage of steam.

2.6.The closed-shaped float resists water attack, there is an overflow gas-emission hole on the bucket, which can effectively prevent vapor locking, air blocking phenomenon. (non-condensing high temperature air can also be exhausted),

2.7 Combined with lever machines can be made into high-pressure valves

Double-valve-seat differential-pressure machinery and SCCV closing mode

When SCCV closing mode and double-valve-seat differential pressure machinery are installed in the same unit,they will have a long life, when the condensation water largely increases, the bucket loses buoyancy and then machinery reversely seal,so as to generate pressure difference, the main valve opens and large displacement is obtained.Using steam equipment and promptly starts to develop the heat effciency of the machine up to the hilt.

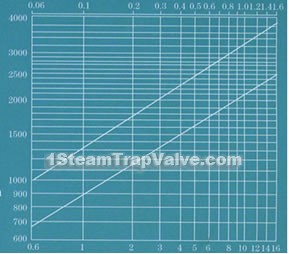

flow rate chart

Working pressure difference Mpa

Main External And Connecting Dimensions

| Production Type | Nominal Diameter DN | connective mode | useful pressure range (MPa) | Max. permitting Temperature?? ℃ | Material Of Body | Material For Main Parts | (mm) External Dimensions | |||

| L | H1 | H2 | W | |||||||

| ER105 (CS15H-3.7) | 20~40 | internal thread ZG1/2~11/2 | 0.01~0.3~0.7 | 220 | WCB | SUS (3Cr13) | 200 | 160 | 135 | - |

| ER105F (CS45H-3.7) | 15~25 32~50 | Flange | 0.01~0.3~0.7 | 220 | WCB | SUS (3Cr13) | 270 | 160 | 135 | - |

| ER110 (CS45H-5.12) | 15~25 32~50 | Flange | 0.01~0.5~1.2 | 220 | WCB | SUS (3Cr13) | 310 | 160 165 | 131 167 | - |

| ER116 (CS45H-7.16) | 15~25 32~50 | Flange | 0.01~0.7~1.6 | 220 | WCB | SUS (3Cr13) | 310 | 160 165 | 131 167 | - |

| ER120 (CS45H-8.16) | 40~65 | Flange | 0.05~0.8~1.6 | 220 | WCB | SUS (3Cr13) | 420 | 175 | 214 | - |

| ER25 (CS45H-25 -40-64) | 15~50 | Flange | 0.05~2.5~4.5~6.5 | 425 | WCB | SUS (3Cr13) | 380 | 210 | 180 | 345 |

| ER105 (CS45H-25 -40-64) | 15~50 | socket weld | 0.05~2.5~4.5~6.5 | 425 | WCB | SUS (3Cr13) | 380 | 210 | 180 | 345 |